Pilot: Dan Tracy

Plane: Lake Sawyer Hawks had the honor of listening to Dan Tracy describe the level of detail and effort required to build models and compete for the Wakefield Cup. Dan related may interesting facts and experiences with this fascinating and demanding hobby. Electronics have replaced mechanical timing mechanisms used on the early models. Wakefield is an endurance event where the objective is to stay aloft for 3 minutes in the early rounds.

Pilot: Dan Tracy

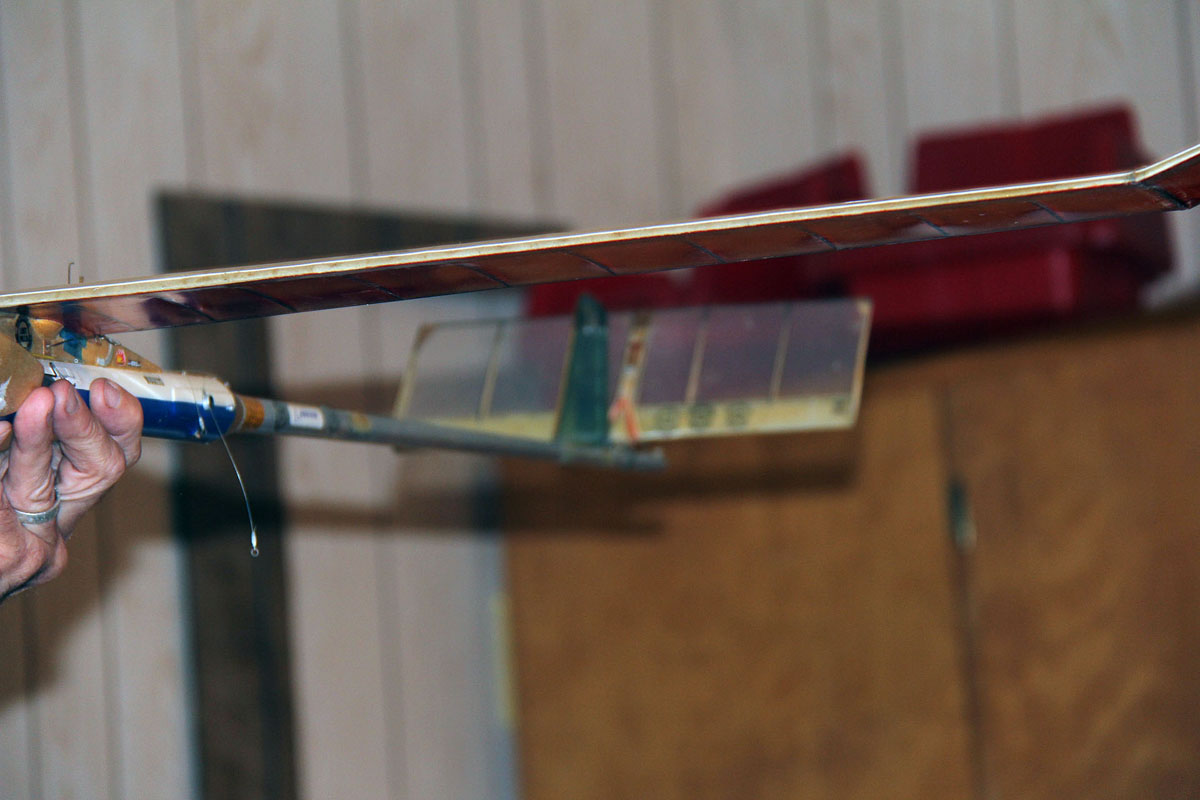

Plane: Dan demonstrating assembly and features of a Wakefield International Cup competition aircraft. Horizontal stabilizer Mylar covering is only 0.0025 inches thick.

Pilot: Dan Tracy

Plane: Numerous parts and spare assemblies that must be carefully packed for shipping across the U.S. or to foreign countries to compete for the Cup.

Pilot: Dan Tracy

Plane: Numerous flight functions are controlled by a mechanical timing mechanism.

Pilot: Dan Tracy

Plane: Model contains many composite materials for optimum strength at minimum weight.

Pilot: Dan Tracy

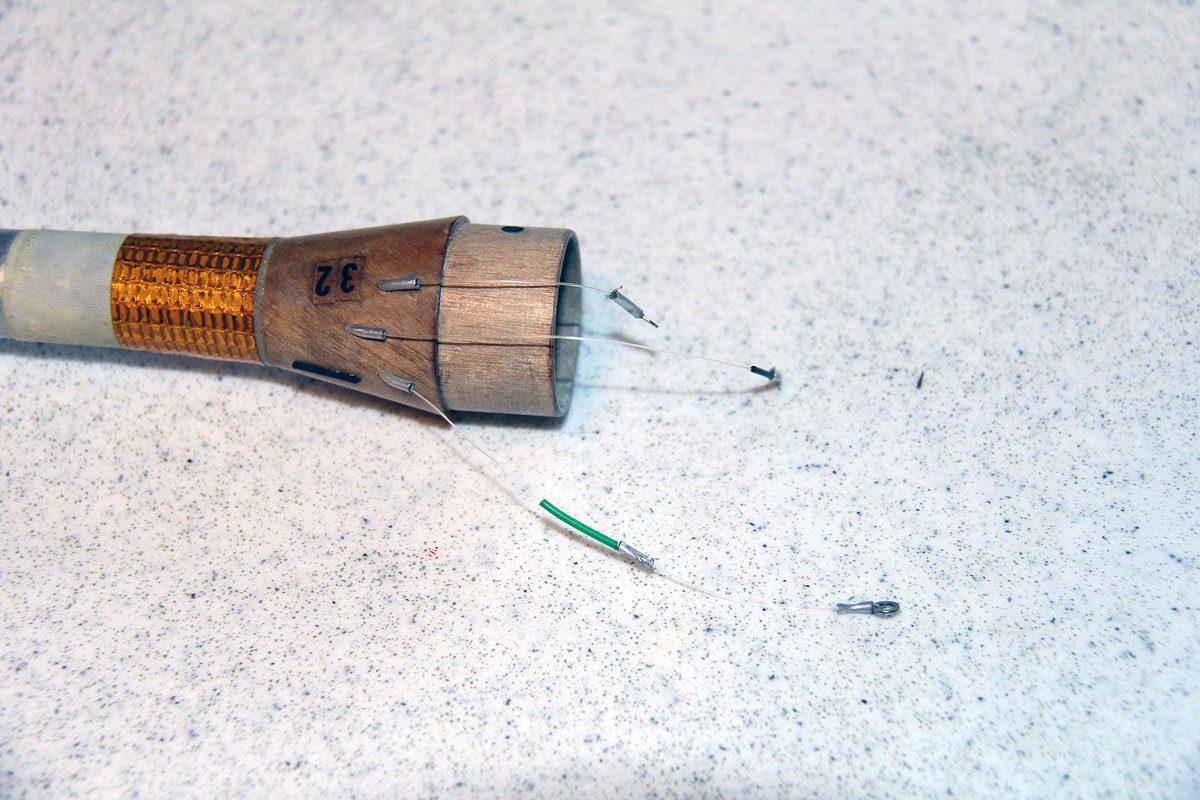

Plane: Many small parts are all custom fabricated for light weight and strength.

Pilot: Dan Tracy

Plane: Horizontal stabilizer control mechanisms.

Pilot: Dan Tracy

Plane: Installing aluminum tube over rubber motor to protect model if the motor fails and releases energy with explosive force.

Pilot: Dan Tracy

Plane: Winding motor that will propel the aircraft when launched straight up to 350 to 400 feet in altitude.

Pilot: Dan Tracy

Plane: Attaching propeller assembly that has catch mechanism to stop blades precisely and allow folding back against fuselage without hitting wing.

Pilot: Dan Tracy

Plane: Ratchet mechanism allows adding turns to rubber motor just before launch for maximum energy storage.

Pilot: Dan Tracy

Plane: Rubber motor weight is limited to 35 grams. In the early days 50 grams was allowed. More rubber allows more energy storage.

Pilot: Dan Tracy

Plane: Motor stop holds propeller until launching hand releases fuselage, which allows maximum thrust without awkward holding of propeller or early release.

Pilot: Dan Tracy

Plane: When motor has expended energy, horizontal stabilizer moves to glide position and rudder guides aircraft in a circular orbit of about 200 feet.

Pilot: Dan Tracy

Plane: Flight ready aircraft weight can be a minimum of 8.1 ounces

Pilot: Dan Tracy

Plane: When launching, upwind sensors are used to detect thermals and determine the optimum time to initiate a flight.

Pilot: Dan Tracy

Plane: If aircraft has remained aloft for the 3 minute required time, the horizontal stabilizer goes into breaking mode to bring the model gently down to the ground.

Pilot: Dan Tracy

Plane: Folding propeller mechanism and nose cone. It takes Dan about 1 year to fabricate and assemble all the precision parts for a competitive aircraft.